Train Positioning

Work Crew Safety

Wheel Defect Detection

Lost Wagon

Detection

Detection

Derailment Detection

Monitor driver behaviour

Predictive Maintenance

Rail Break Detection

fiberRAIL® - Track and Monitor Everywhere

Benefits of fiberRAIL®

INCREASE PRODUCTIVITY

Seamless positioning enables „moving block interlocking” for increased line capacity

Enhance Safety

Detect and react before accidents or damage happen

Save Costs

No track- or train-side installation // zero maintenance

fiberRAIL® offers leading-edge solutions

for railway and infrastructure operators

Take a look at the fiberRAIL® information Flyer!

Derailment Detection

- No automatic detection for partial derailment today

- High potential for damage and accidents, high impact

- Immediate detection by fiberRAIL® can safe lifes and reduce repairment costs

Wheel Defect Detection

- No automatic detection today

- Flat spots damage rail infrastructure

- Early detection by fiberRAIL® significantly lowers repair costs

Rail Break

- No automatic detection today, only observations by the driver

- High potential for damage and accidents, high impact

- Early detection by fiberRAIL® prevents accidents and significantly lowers repair costs

Work Crew Safety

- Work crews depend upon warning about approaching trains

- fiberRAIL® provides spot-on, real- time warnings that work independently of interlocking. Warning message can be sent directly to mobile devices.

- fiberRAIL® increases redundancy and avoids human error.

Lost Wagons

- Pose a major threat for train traffic and infrastructure.

- A lost wagon may stay undetected until it passes an axle counter

- fiberRAIL® alarms about lost wagons without delay and everywhere on track, thereby prevents severe accidents, personal injury and loss of life

Train Positioning

- fiberRAIL® provides real-time position and speed of all vehicles in your network

- No train-side equipment needed (GNSS & GMS-R)

- Accurate, real-time passenger information

- Usage and wear statistics on your infrastructure supports predictive maintenance

Predictive Maintenance

- Anticipate failures by online monitoring of key parameters

- Early planning and timely maintenance save cost

- fiberRAIL® provides seamless and continuous data of all your assets for predictive maintenance

Encourage sustainable driver behavior

- Excessive acceleration and braking cause severe wear of the rail infrastructure

- Online detection and documentation of excessive driver maneuvers

- fiberRAIL® provides seamless and continuous data to raise driver awareness

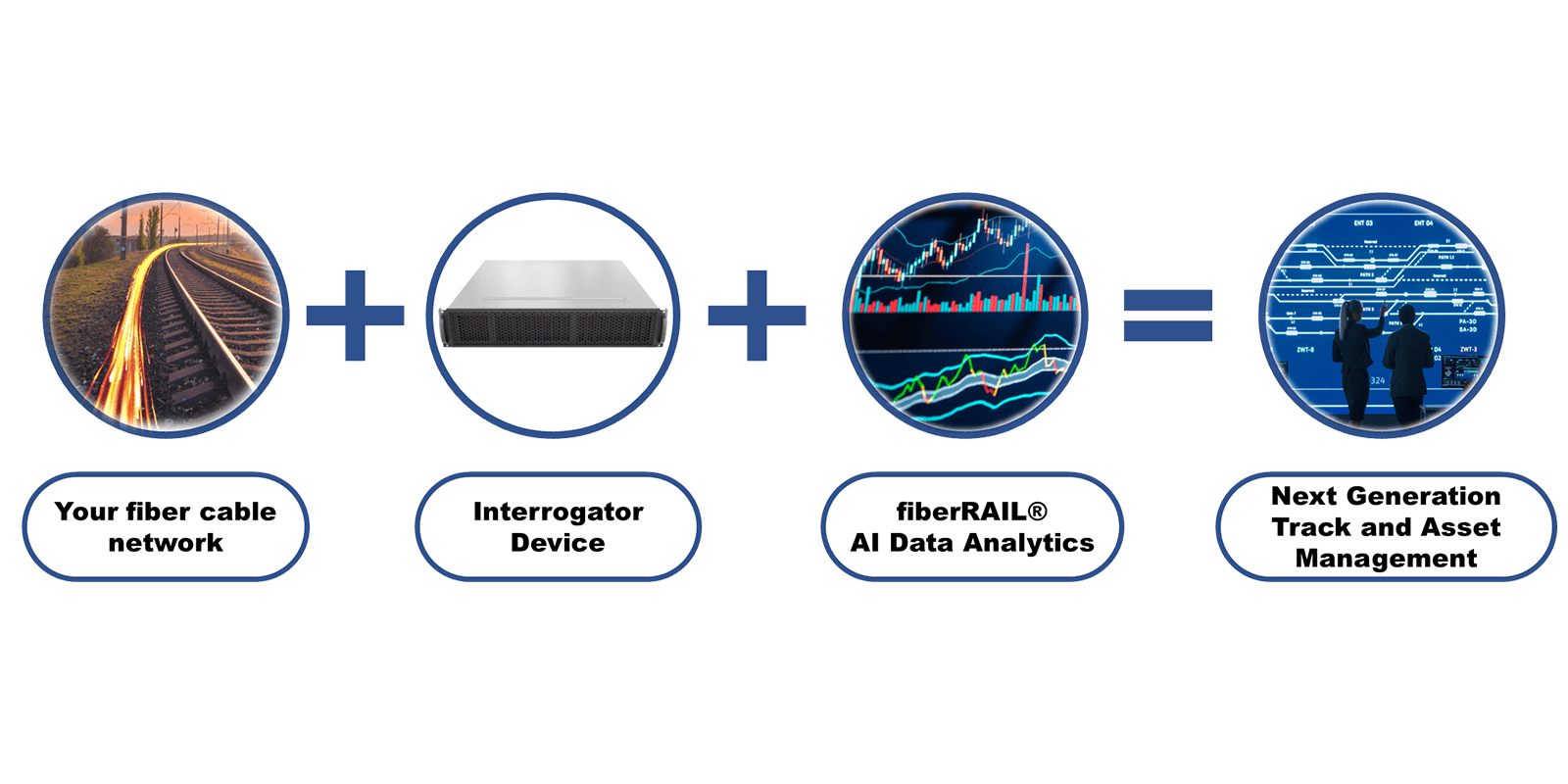

Technical Specifications

Basic Performance

-

- Range: up to 50 km, 100 km with repeater device

- Position and event update rate: 1 per second

- Basic train monitoring: train position, train length, train speed, movement direction

- Trains monitored simultaneously: up to 100

- Position resolution: approx. 1 m

- Position accuracy: approx. 10 m

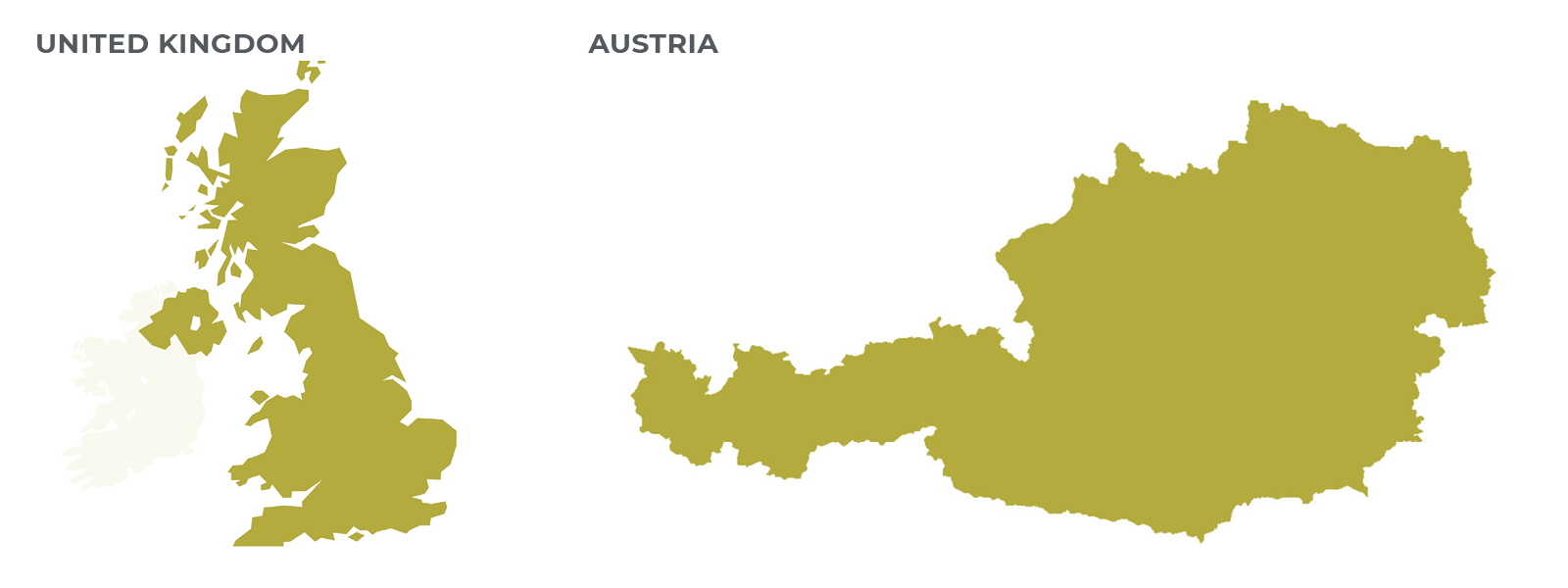

References / Pilot Operations

- 3 interrogators

- 100+ km of track

- 1 year trial installation

- real-time operation

- 8.8 km track

- permanent installation

- real-time operation

- rail-foot cable

- High performance/high speed track

- 20 km

- 4 weeks data analytics

- rail on ballast and concrete

- cable trench

- Tunnel

- 26 km track

- 20 days real-time operation

- 2141 trains

- cable trench

- 10 km track

- data analytics for flat spot detection

- 39 freight trains

- cable installation in ground

- 1 interrogator

- 40km track

- wheel defect monitoring

- real-time operation

- 6 months trial

- 1 interrogator

- 55km track

- real-time operation

- permanent operation (ongoing)